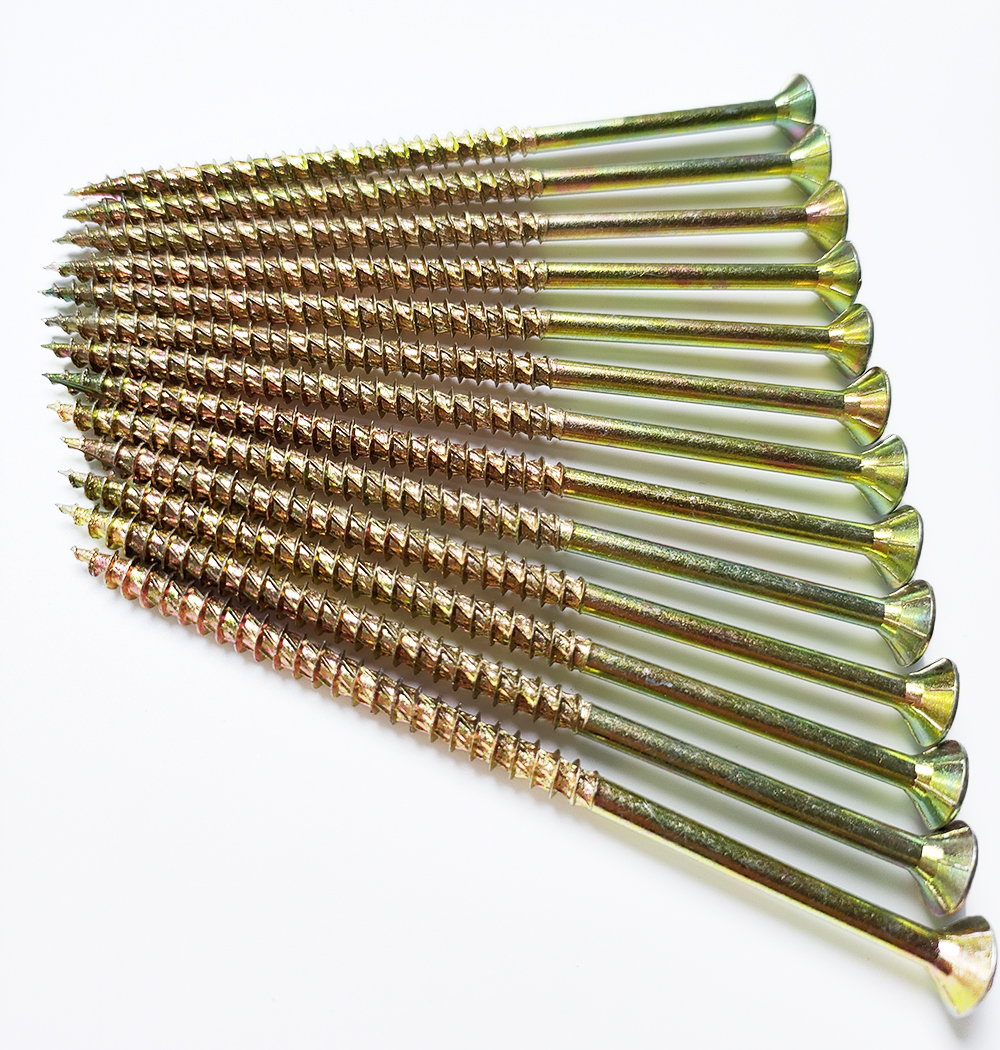

chipboard screws

place of origin:Shandong, China

Shandong, China:flat

model number:2 3/8 Inch

Screw material:Steel

Head type:Pozidrive

Surface treatment:Galvanized

Description

|

Produce Name

|

Chipboard Screw With Cutting Tails

|

|

Material

|

Carbon Steel

|

|

Surface treatment

|

Zinc Plated

|

|

Head type

|

Pozidrive Head

|

|

Point

|

Type-17 Point

|

|

Length

|

2-6 Inch

|

|

Diameter

|

0.157-0.236 Inch

|

|

Package

|

Carton + Pallet

|

|

Application

|

Fix wood,chipboard,fiberboard and other materials

|

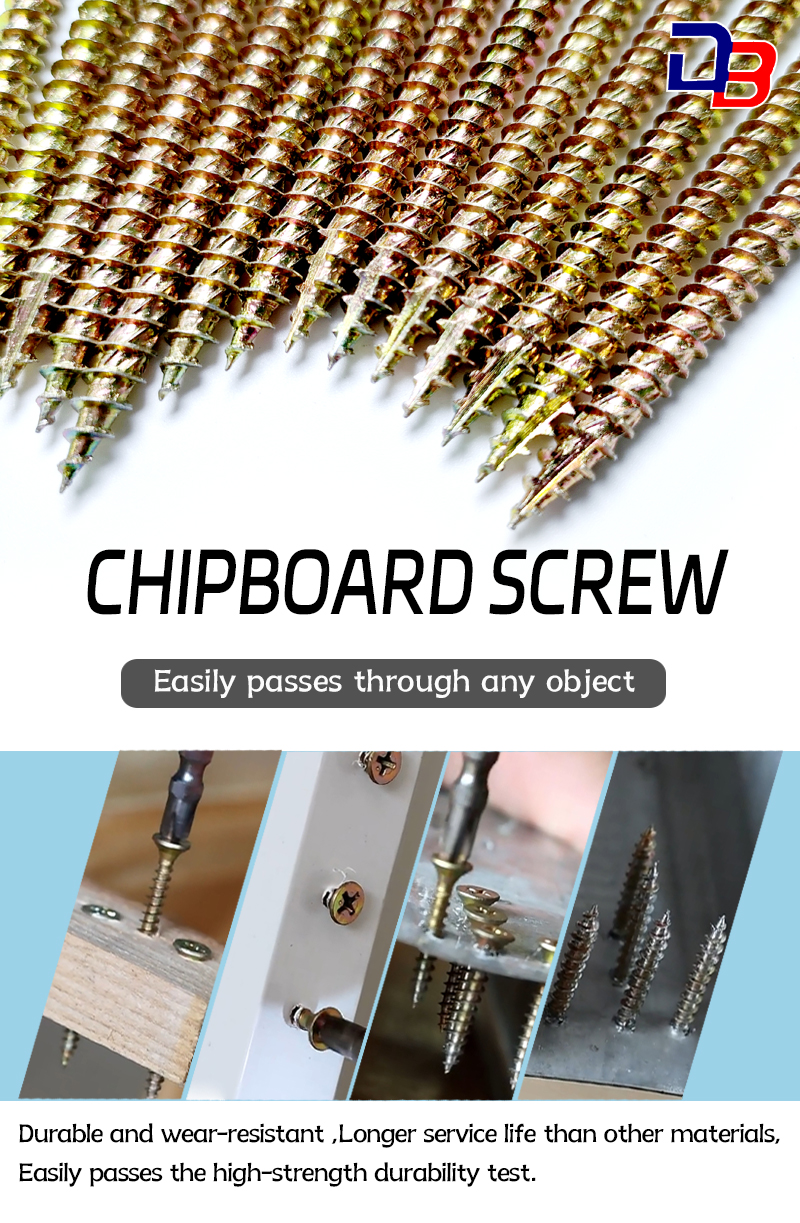

A **chipboard screw with cutting tails** is a specialized type of screw designed for use in chipboard, MDF, plywood, and other engineered wood products. These screws are engineered to provide strong holding power and reduce the risk of splitting the material. Here are some key features and benefits:

### Key Features:

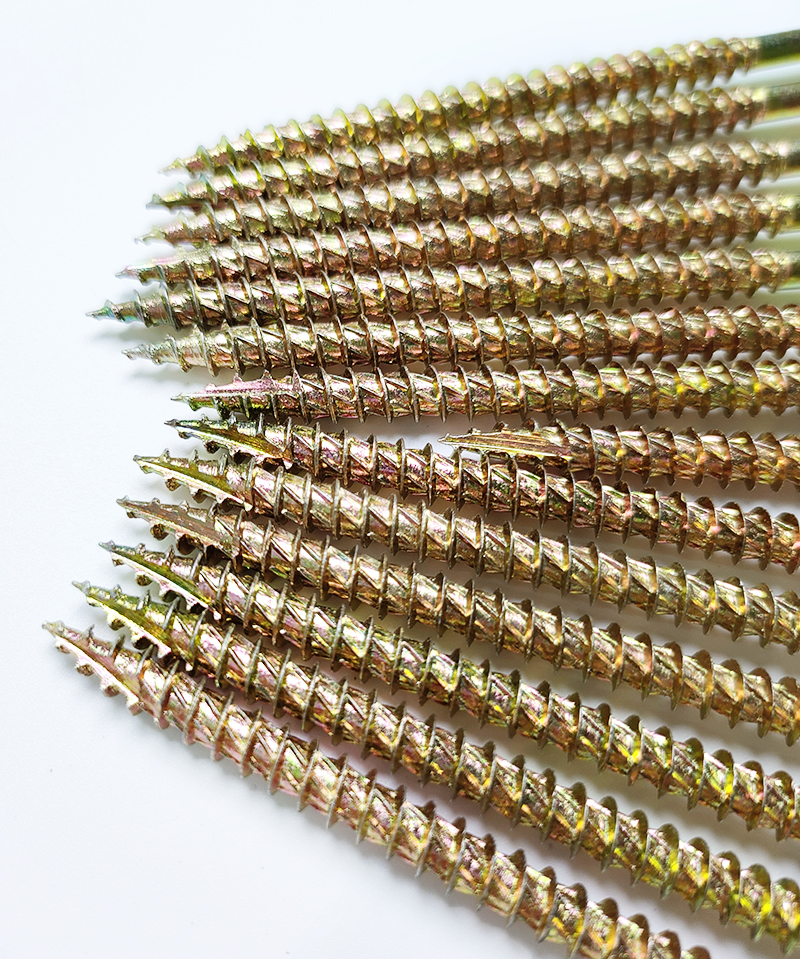

1. **Cutting Tails**:

– The screw has a unique design with cutting edges or “tails” near the tip. These tails help to cut through the material, reducing the need for pre-drilling and minimizing the risk of splitting the wood.

2. **Sharp Point**:

– The sharp point allows for easy penetration into the material, making it easier to start the screw without a pilot hole.

3. **Thread Design**:

– The threads are designed to grip the material firmly, providing excellent pull-out resistance and holding power.

4. **Self-Tapping**:

– These screws are self-tapping, meaning they create their own threads as they are driven into the material.

5. **Material and Coating**:

– Typically made from hardened steel, often with a corrosion-resistant coating (e.g., zinc-plated or gold passivated) to enhance durability.

### Benefits:

– **No Pre-Drilling Required**:

The cutting tails and sharp point eliminate the need for pre-drilling in most cases, saving time and effort.

– **Reduced Splitting**:

The design minimizes the risk of splitting chipboard or other engineered wood products.

– **Strong Hold**:

The thread design ensures a secure and durable connection, even in softer materials.

– **Versatility**:

Suitable for use in chipboard, MDF, plywood, and other composite materials.

### Common Applications:

– Furniture assembly (e.g., flat-pack furniture)

– Cabinetry and joinery

– Construction of shelving units

– Fixing wood panels or boards